Watch straps usually play second fiddle to the Breitling fake watches online they hold in place. Not at La Montre Hermès, which takes its leather goods as seriously as it does its watchmaking. In this feature, Gisbert Brunner explores how a fine leather watch strap is crafted.

For many watch fans, connoisseurship stops at the case lugs; the watch strap, a temporary, easily replaced accompaniment, is no more worthy of study than a paper napkin. That isn’t fair. Fine watch straps reward scrutiny the same way fine watch movements and cases do. Equipped with a little knowledge of leather-crafting techniques, a connoisseur can become as expert a judge of the former as of the latter.

A good place to start one’s study is at the world-famous, crème-de-la crème leather goods company Hermès. The company makes some 120,000 straps per year, not only for its own collection of Hermès-brand watches but for those of Parmigiani Fleurier as well.

The company developed its leather-making prowess long before the wristwatch came along. In 1837, Thierry Hermès, a saddler and maker of other equestrian tack, opened a workshop in a back courtyard on Rue Basse de Rempart in Paris. The quality of his products soon earned him an enviable reputation. He moved to the Faubourg Saint-Honoré and, over the decades, Hermès and his descendants diversified into wallets, handbags, belts and luggage, earning the family brand considerable renown. In the early 20th century Hermès began marketing wristwatches manufactured by outside suppliers and equipped with its own leather straps. It introduced its first Hermès-brand wristwatches in 1928.

Today, Hermès makes its watch straps in two facilities. One is in Switzerland, in the town of Brügg, near Bienne, where Hermès’s watchmaking offshoot, La Montre Hermès (founded in 1978), assembles its watches. There, in a small atelier in the big, modern-looking factory, 12 highly trained strap makers ply their craft. The other facility, where 30 of the company’s strap makers work, is in Paris.

One-third of the company’s straps are made from alligator; the rest are made of calfskin, buffalo or ostrich hide. As is true of all of Hermès’s leather goods, the watch straps are made from only the most meticulously selected raw material. Only about 40 straps can be made from each calf hide because Hermès uses only the skin from the calf’s back. No more than four straps can be made from an alligator skin because only the belly portion is used; the remainder of the scaly skin is incinerated.

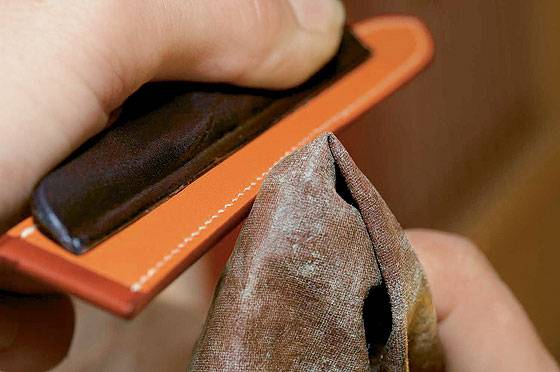

It takes at least two hours to make each standard strap, and considerably longer to make customized ones. Each strap consists of three layers: the upper leather, visible when the best Panerai replica watches is worn; a textile lining beneath it; and the lower leather, which comes into contact with the wearer’s wrist. Once the leather blanks have been stamped, their edges are beveled until they are paper-thin. This ensures that they don’t bulge after they are folded over and stitched down.

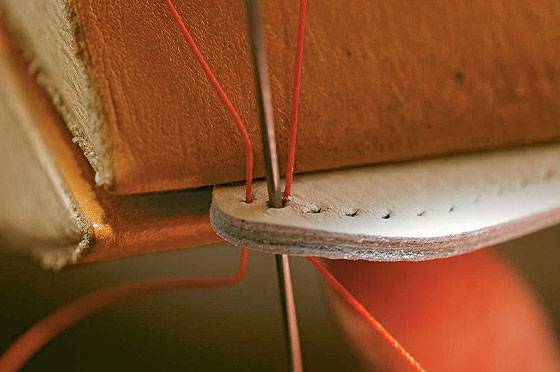

Glue is an important bonding material for strap making, but stitching plays an even bigger role. There are two main varieties of seams: machine-stitched and saddle-stitched. The latter requires two needles plied in opposite directions. The thread is knotted in the last few millimeters of the strap, where the “tunnel” for the spring bar is located. Artistry and technical skill are equally important in sewing a saddler’s seam. The strap’s loops are particularly challenging: the craftsman makes six perfectly placed stitches to merge the loop’s ends. Machine-sewn seams also require deftness and experience: each material must be stitched at its own particular angle, so the machinery must be adjusted prior to sewing.

After the needle comes the hammer. Hermès will not accept protruding seams, so the strap makers gently rap and tap with their hammers until each strap is flat and smooth.

The next step, processing the edges, usually requires at least 15 separate tasks. Each is executed by hand: abrading, waxing in the desired color, heating to between 176 and 212 degrees Fahrenheit, and polishing. Depending on the strap, the entire procedure must be repeated as often as five times. Afterward, slim grooves are embossed into the upper leather parallel to the strap’s margins.

Finally, the atelier’s director scrutinizes each strap under a loupe. If he discovers no flaws, the strap is punched with marks specifying its material and year of manufacture. The letter “K,” for instance, denotes bands made in 2007. An “L” means the strap was made at La Montre Hermès in Bienne and a “V” means it was made in Paris.

Before a particular strap style goes into serial production, it has already been tested for durability. This process occurs off-site, at the Laboratoire Dubois, an independent material-testing institute in La Chaux-de-Fonds. There, the straps undergo the so-called “Chronofiable” trials, which check their long-term performance under conditions straps rarely encounter in the real world. The strap must stand up to these torture tests in order to be approved for serial production.

In all likelihood, Hermès will one day shift all of its strap production to the La Montre Hermès facility. Right now, there is not enough floor space there to do so. Fortunately, Hermès owns a neighboring lot where it plans to build an annex. When completed, it will house a capacious leather warehouse and new workbenches.

Hermès will then need to find and train qualified personnel. Artisans such as these are at least as valuable as watchmakers; Hermès suffers a major loss whenever an employee departs because it takes so long to bring new employees up to the company’s high standards. Steve Scheuber, head of the strapmaking atelier, says, “At least one year passes at any new replica Breitling watches strap manufacturing site before 80 percent of the straps made there are acceptable.”